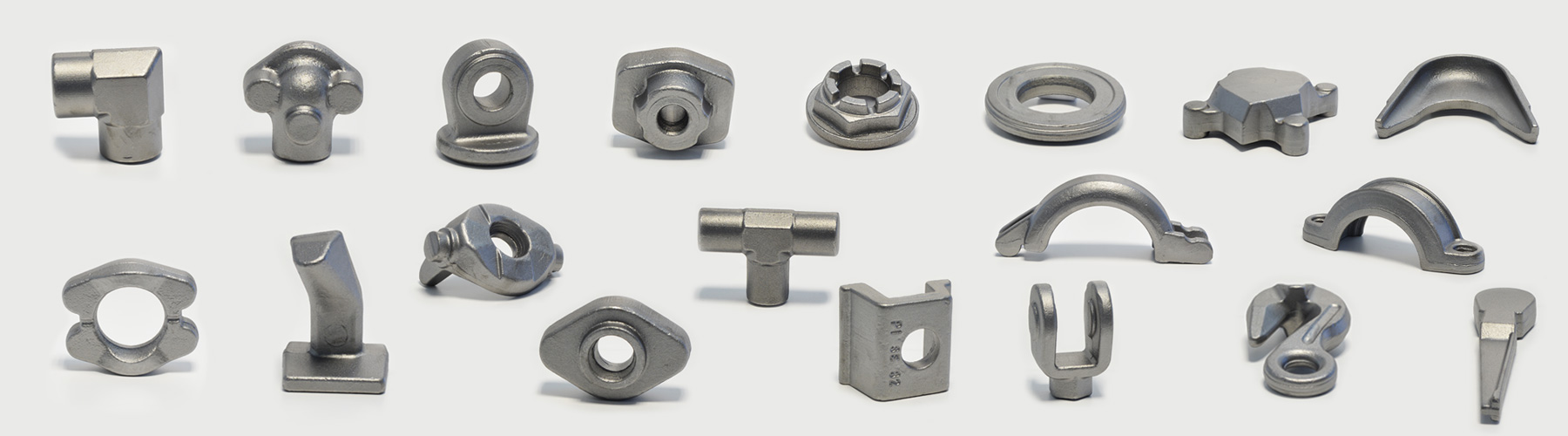

Production

Stamperia Segrino offers a wide possibility of production, thanks the process of hot forging iron and steel. The decision to adjust production only on drawing provided by the customers, allows us to fully meet the requests. This is possible thanks to the use of machines consisting in: CNC high speed milling machines with which we build the molds to be then used for forging. This significantly reduces the time needed for equipment preparation and consequently also that to obtain the finished product.

The production cycle of our products

Stamperia Segrino production cycle consist in seven different phases, that allow to reach a perfect product.

-

Drawing

Most of the works of Stamperia Segrino comes from customer drawings. The result is therefore a unique and customized product.

-

Transfer of the 3d model using cad design

Thanks to the use of computerized systems, Stamperia Segrino achieves the three-dimensional modeling of the piece to be forged. In this way the drawing of the raw product is optimized for forging, whereas all the parameters and the machining necessary to obtain them.

-

Construction equipment via cam and numerical control milling machine

Once obtained the 3D to be used for the production, this is used as a reference for the milling. Exploiting computerized machines(CAM) and numerical control milling, we built all the equipment necessary to make the product designed in the early stages. The use of numerical control milling machine allows to automate the production process and to greatly expand the range of shapes achievable with a single work program.

-

Cutting with automatic cutter

At this stage we use automatic cutter for cutting steel coming from certified Steelworks.

-

Heating in induction furnace

Heating in induction furnace is an efficient and accurate method of heating, with which the metallic material warms thanks to the passage within an electric coil. Use this type of heating means to work in absence of flame and without the creation of the combustion-related waste.

-

Forging

At this stage we realize the forging process. Thanks to line of presses (1000 and 750 tons) we can ensure optimum functionality in relation to customer needs. The vast knowledge of the hot forging process allows us to be able to obtain a product faithful to the drawing and excellent mechanical strength.